Managing Legionella in Water Systems During the COVID-19 Pandemic

Why this guidance? While water systems may not seem to be high on the priority list during the COVID-19 pandemic it is important for the health and...

There are many questions to consider when deciding how to heat and cool your building. In many cases, the mechanism that you choose to heat and cool your building can have impressive effects on lowering your overall energy costs. We have gathered some of the frequently asked questions that people ask us about closed-loop systems. If you are considering installing a new closed water loop system in your building or already have one, click HERE to connect with one of our industrial water treatment professionals. IWC Innovations offers a variety of cost saving solutions for your closed-loop water system. We are ready to be your partner in water.

Is Closed-Loop Cooling Water Worth it?

Yes and No. There is a reason the air conditioner you have at home doesn’t also cool the water that flows throughout your home. Using water for cooling is often only cost effective when dealing with large buildings. IWC services closed-loop cooling water in a variety of buildings ranging from local post offices to fifteen story Class A office spaces. A closed-loop system often has greater upfront cost for installation but maintenance costs over time are typically significantly lower. A proper closed-loop water system design will manage the benefits of water cooling and the associated costs.

What chemicals are used in closed-loop systems?

Every company has their preferred method of treatment. At IWC, we use a proprietary blend of compounds that provide corrosion inhibition in a closed system. With improper treatment, water touches the metal directly which can lead to corrosion, rust and eventual failure. With proper treatment a single layer of metal molecules (of insignificant depth) are consumed and replaced with a compound that is bound to the metal. This creates a hydrophobic layer that water can not penetrate, thus saving the metal from corrosion.

The second chemical that we use is a non-oxidating biocide. Oxygen in closed loop systems can do damage itself. Free oxygen and copper can form copper oxide. Copper oxide is water soluble and can dissolve your pipes. IWC uses a biocide that kills the bacteria that comes in from city water, but also scavenges oxygen. This depletion of oxygen kills the bacteria and keeps the system free from growth and damage.

How to remove air from closed loop systems?

Removing air is important to your water system’s long term success. Air in the system can damage pumps. Closed-loop systems are designed not to have any air in the system. Additionally, as stated previously, ambient air has oxygen gas, which can damage the copper piping. To remove the air you have to “burp” the system. Typically any air in the system will collect in the side stream filter or pot feeder.

This can be opened and filled to just slightly overflowing to remove as much of the air as possible. There are also often valves at distal locations that regulate air in the system automatically. If you are having issues with air in your system, click HERE, to get connected with one of our closed loop water treatment professionals. IWC Innovations has serviced a diverse set of systems in a variety of different buildings. We are able to see where you are and provide the most cost effective way to get your system where you need to be.

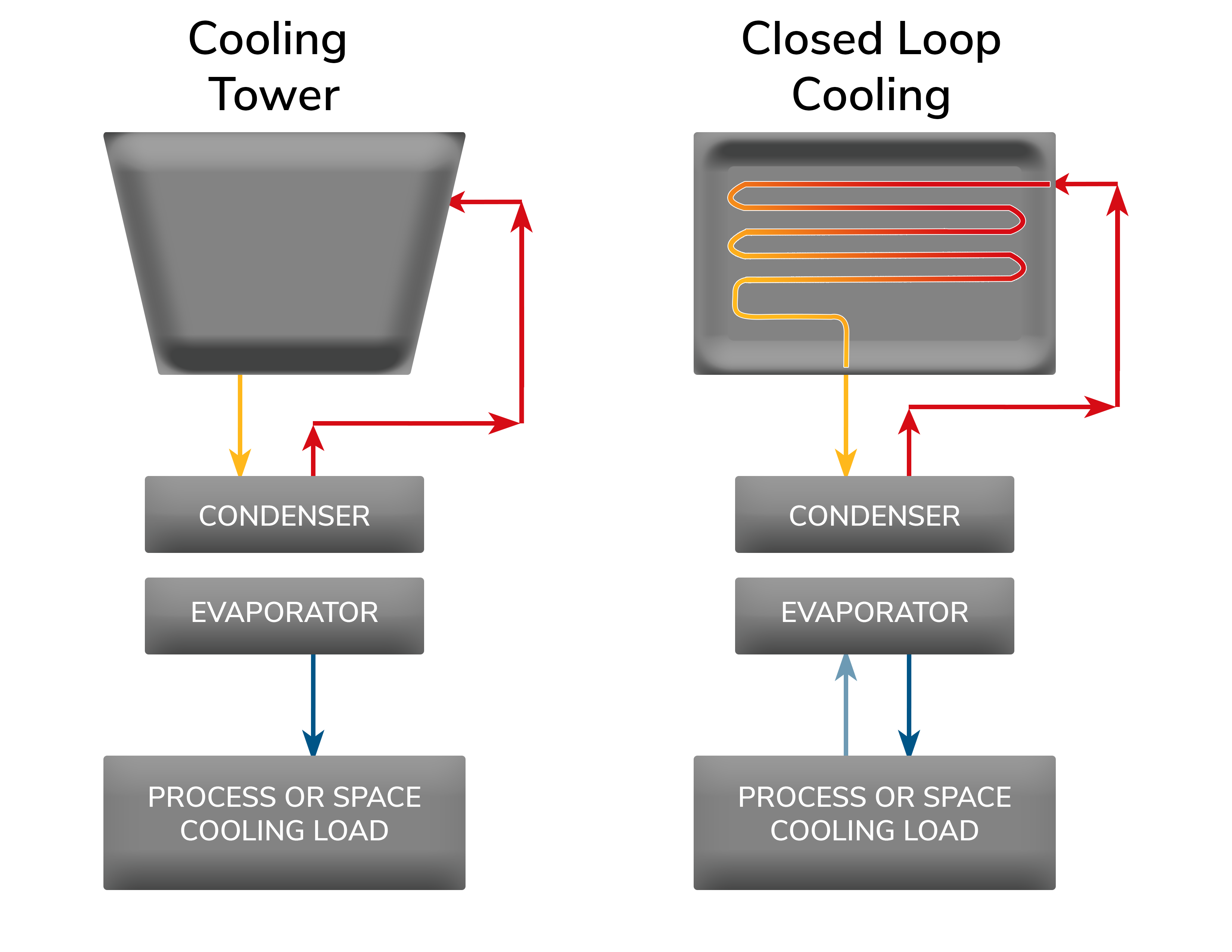

What is the difference between an open and closed loop system?

One is open and one is closed.

-1.png?width=352&name=ClosedLoop%20vs%20OpenLoop%20(1)-1.png)

The difference is a little more complicated than that but effectively one system is open to the environment and the other is closed to the environment. Open systems have very different needs and requirements. An open system you may be familiar with is a cooling tower. The air is cooled in the environment and thus there are more things that can get in the system both physical and bacteriological. Often the best system has both an open and a closed system. The open system provides cost effective cooling but is difficult to keep clean due to external influences in the environment. As well, it is difficult to keep at a consistent temperature due to the large mass of water that must be cooled. Often, an open system will go through the cooling tower and then through a heat exchanger which transfers the cooling power to the closed system without mixing the water. Thus the water going through the building and to the individual units can be easily cleaned and maintained and you get the cost effective cooling from the cooling tower.

If you have water in your building we can help you manage it. We have over 30 years of experience in the water treatment industry and are ready, able and willing to be your partner in water. Contact us to talk to our commercial water treatment professionals about what problems we can solve for you.

Johnathan Ryder,

Commercial Water Treatment Specialist

Operations Manager for IWC Innovations Water Treatment Division

Follow me! @That.water.guy

Why this guidance? While water systems may not seem to be high on the priority list during the COVID-19 pandemic it is important for the health and...

With mandated building closures across the United States due to Covid-19, IWC, would like to remind building owners, facility managers, and building...

How Does Legionella Grow Within the Water System?