Cooling towers play a vital role in the majority of industrial and commercial establishments, serving as essential components. Their primary function is to cool water utilized for a wide range of processes and applications. The heat transfer is done one of two ways: sensible heat and latent heat. Sensible heat is the heat transfer that is dependent upon changes in water temperature. Latent heat is the heat transfer related to the changes in physical state.

Cooling towers utilize water as the primary medium for their operation. Whenever a pound of water evaporates, a significant amount of heat is released. In the context of heat transfer involving water, evaporation proves to be approximately 1,000 times more efficient compared to sensible heat transfer. While the precise value may vary slightly, the industry widely acknowledges the standard measure of heat energy per pound, expressed as British thermal units (Btu).

The fundamental purpose of cooling towers is to establish a highly effective heat transfer system by facilitating the interaction between air and water in an efficient and prompt manner. Evaporation accounts for a substantial portion of heat dissipation, typically ranging from 75 to 95 percent, while the remaining 5 to 25 percent is removed through convection. This well-balanced combination ensures optimal cooling for various processes, equipment, or buildings. Let’s dive into the basics and address the fundamental question: How do cooling towers operate?

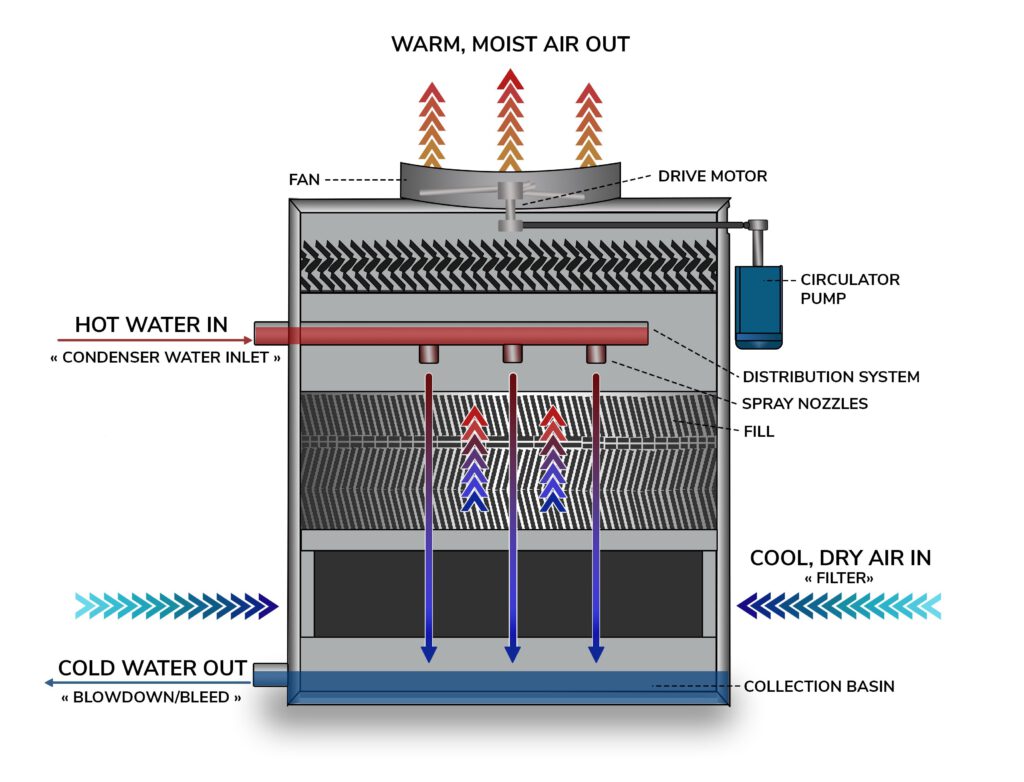

Here’s a general overview of how cooling towers work:

-

Hot water enters the cooling tower: The cooling tower receives hot water from an industrial process or a heat exchange system.

-

Water distribution system: The hot water is distributed over the fill material inside the cooling tower. Fill material consists of a series of thin sheets or closely spaced plastic or metal elements, which increase the contact surface area between the water and the air.

-

Airflow and evaporation: As the hot water flows over the fill material, it is exposed to a flow of air. The air can be forced through the tower using fans or generated by natural draft (through the stack effect). The airflow causes some of the water to evaporate, taking away heat in the process.

-

Heat transfer: The evaporation of water removes heat from the remaining water, reducing its temperature. This is because the heat energy required for evaporation is drawn from the hot water, causing it to cool down.

-

Water collection: The cooled water collects at the bottom of the tower, known as the cold water basin.

-

Circulation: The cooled water is then pumped back to the industrial process or heat exchange system to absorb more heat and repeat the cycle.

-

Discharge of warm, moist air: As the air passes through the cooling tower and absorbs moisture, it becomes warm and saturated with water vapor. This warm, moist air is discharged into the atmosphere through the top of the tower or through exhaust fans.

Cooling towers can be either “open” or “closed” systems. Open systems allow for direct contact between the water and the surrounding air, while closed systems use a heat exchanger to transfer heat indirectly, without direct contact between the water and the air.

By continuously cycling the water through the tower, cooling towers help dissipate excess heat and maintain optimal operating temperatures in industrial processes or power plants, preventing equipment overheating and ensuring efficient operation. The efficiency of your cooling system is influenced by multiple factors. Similar to any other technology, it is essential to conduct thorough research and analysis to assess the viability of adopting new methods. It is advisable to refer to your equipment manuals and guides for valuable insights and guidance. By exercising due diligence and seeking appropriate information, you can make informed decisions about maximizing the efficiency of your cooling system, and as always IWC Innovations is here to assist you every step of the way!