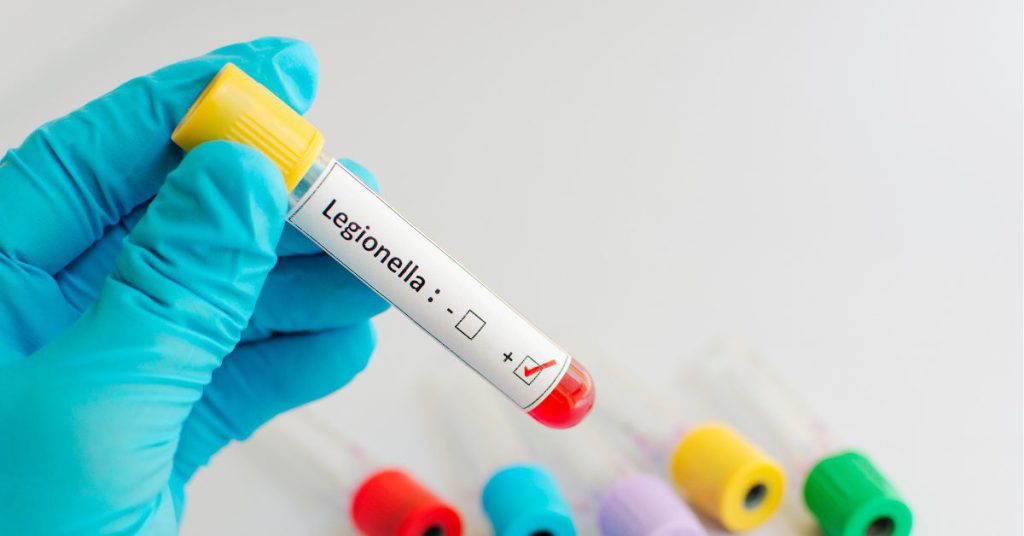

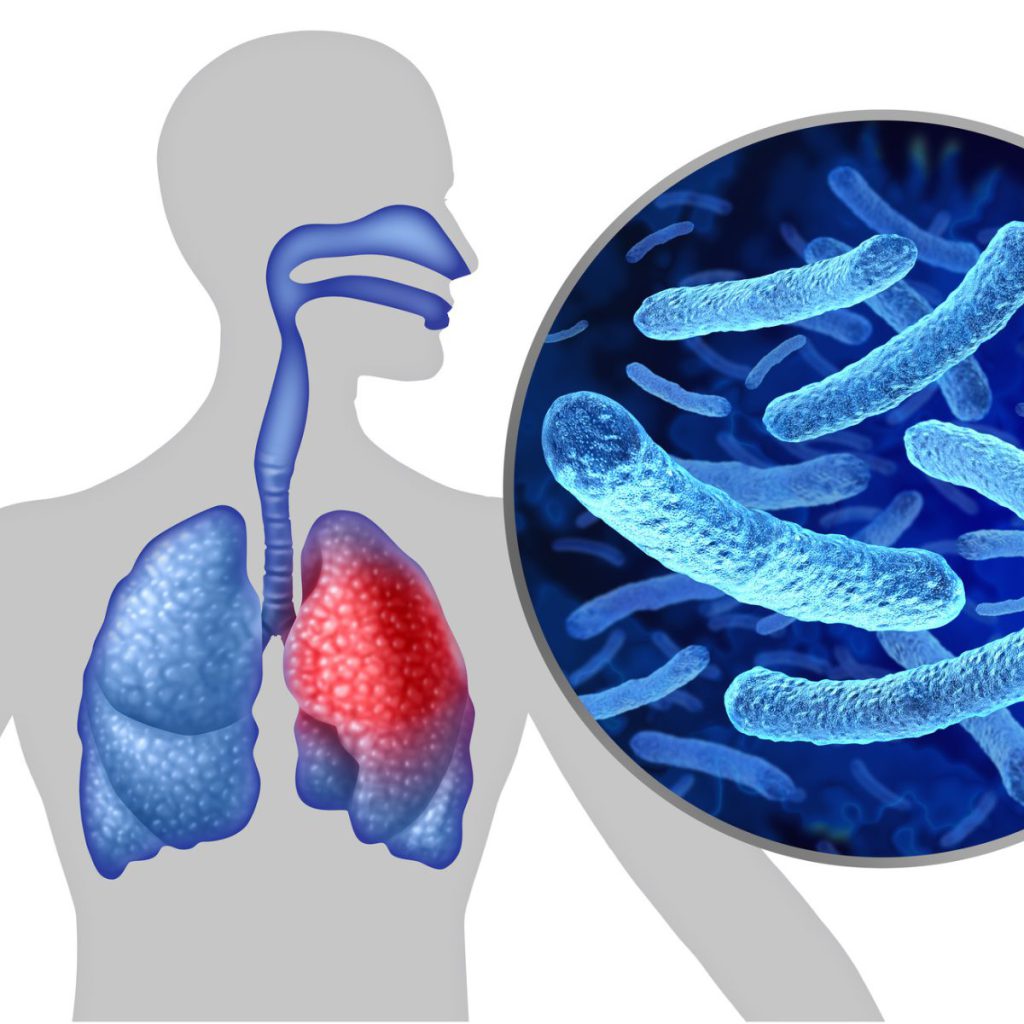

Discovering Legionella bacteria in a building can be alarming for property owners, facility managers, and occupants alike. Because Legionella are the bacteria responsible for Legionnaires’ disease, a serious and sometimes fatal form of pneumonia, its presence requires immediate and strategic action. Understanding what happens next, and how to respond, can help protect building occupants, ensure regulatory compliance, and reduce liability.

What Is Legionella and Why Is It Dangerous?

Legionella are naturally occurring bacteria that thrive in warm, stagnant water systems. Commonly found in building water systems, including cooling towers, domestic hot water systems, decorative fountains, hot tubs, and plumbing fixtures. When contaminated water becomes aerosolized, such as through showers or cooling tower drift, people can inhale the bacteria.

Exposure can lead to Legionnaires’ disease or the milder Pontiac fever (non-pneumonia), with higher risk for older adults, smokers, and individuals with weakened immune systems. Because symptoms often resemble typical pneumonias, outbreaks of Legionnaires’ disease can go undetected without proper Legionella testing.

Step 1: Confirmation Through Legionella Testing

If Legionella are suspected in your facility, the first step is to test your water. After water samples are collected, an accredited laboratory typically performs Legionella analysis using culture methods or rapid testing techniques. Results will identify Legionella concentrations and specific species, such as Legionella pneumophila, the most virulent species, resulting in over 90% of Legionnaires’ disease cases.

Confirmed laboratory results help determine the severity of the issue and guide the appropriate approach and response.

Step 2: Immediate Response

Once Legionella bacteria are confirmed, a Legionella risk assessment should be conducted. This evaluation identifies where the bacteria are present, how they may spread, and who may be at risk. A thorough water system risk assessment examines temperature control, stagnation, disinfectant levels, and system design.

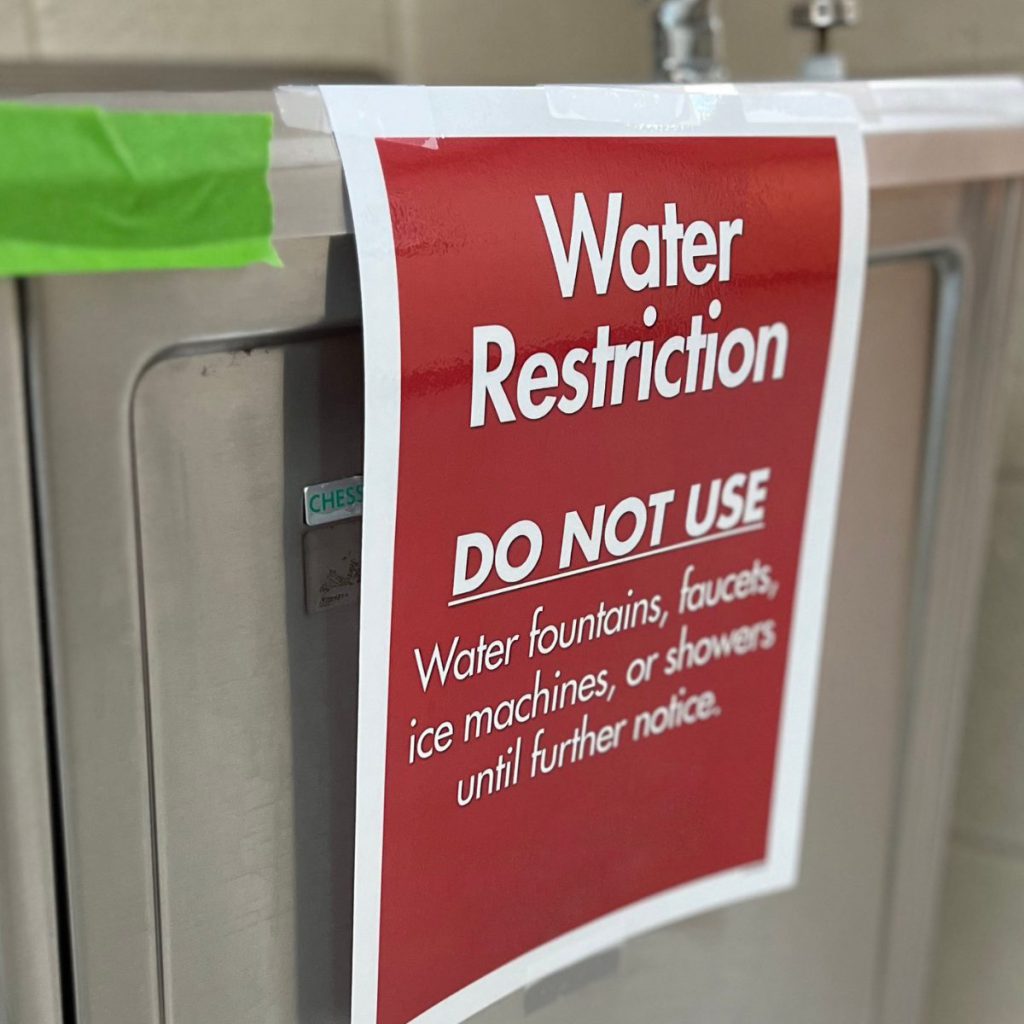

In addition, the facility should implement temporary water restrictions to further reduce risk. These measures may include installing point-of-use filtration devices at faucets and fixtures to limit potential exposure. These controls should remain in place until corrective actions are fully implemented, validated, and confirmed to be effective.

Step 3: Notification and Regulatory Compliance

Buildings that detect Legionella in water samples during internal or routine validation testing are not required to report those findings. Reporting is only required when there is an active case investigation resulting from a clinical diagnosis of Legionella, at which point environmental sampling results may be requested as part of the investigation.

Depending on your state and/or industry, failure to comply with Legionella regulations can result in fines, legal action, and reputational damage. Staying aligned with standards such as ASHRAE 188 and CDC Legionella guidelines is critical.

Step 4: Remediation and Disinfection

After assessment, a targeted Legionella remediation plan is implemented. Common Legionella treatment methods include:

- Hyperchlorination or supplemental chemical disinfection

- Copper-silver ionization system

- Ozone generation system

- Ultraviolet (UV) Disinfection

- Filtration

- Flushing Programs

The goal of Legionella disinfection is to reduce bacteria levels to safe thresholds while addressing the root causes that allowed growth in the first place.

Step 5: Retesting and Verification

Following remediation, Legionella retesting will verify effectiveness. Post-treatment Legionella testing confirms whether bacteria levels have been successfully reduced and whether additional corrective actions are needed.

Documentation of results is also a key component of compliance and risk management.

Step 6: Implementing a Water Management Program

To prevent recurrence, if the facility doesn’t already have one in place, they should establish a comprehensive water management program. A Legionella water management plan (WMP) outlines ongoing monitoring, maintenance procedures, and corrective actions aligned with ASHRAE Legionella standards.

Key components include:

- Routine Legionella monitoring

- Temperature and disinfectant control

- Regular system inspections

- Staff training and documentation

Adherence to a proactive Legionella prevention plan (WMP) that is compliant with ASHRAE Standard 188 significantly reduces the likelihood of future contamination.

What Happens If Legionella Is Ignored?

Ignoring Legionella growth in water systems can have serious consequences. Beyond the risk of illness or death, building owners may face lawsuits, shutdowns, and long-term reputational harm. Proactive Legionella control is imperative to public health and a critical business necessity.

Protecting Your Building and Occupants

If Legionella growth is found in a building, swift action, expert guidance, and ongoing prevention are essential. Partnering with experienced Legionella management professionals ensures compliance, safety, and peace of mind.

By investing in proper Legionella testing, remediation, and water management programs, building owners can safeguard occupants while minimizing operational and legal risks.

Concerned about Legionella in your building? Proactive testing and a strong water management plan can make all the difference. Contact IWC Innovations today at 866-761-1600