Steps for Cooling Tower Maintenance

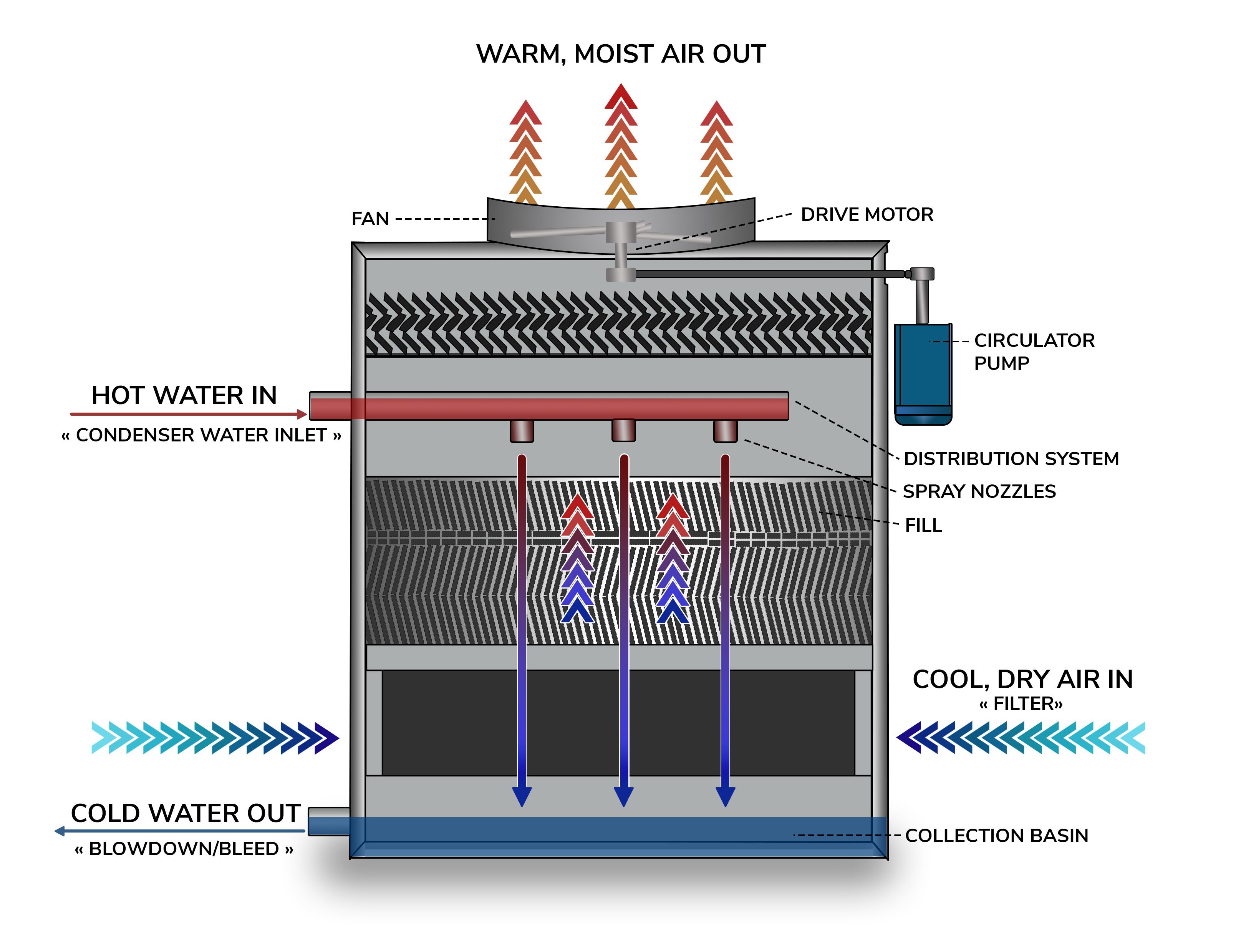

What is a cooling tower? Cooling towers are designed to remove heat from a building. This heat is removed by cooling a stream of water to a lower...

Even though cooling towers otherwise known as evaporative condensers or evaporative coolers are highly efficient at rejecting heat-producing cooling water, they’re not maintenance-free. Over time, nutrients, airborne dirt and debris collect within different components of cooling towers.

|

Fan |

Moves air throughout the system. In evaporative coolers, the fan cools the water as it falls on the condenser tubes on the top. In traditional open cooling towers, the fan forces air into the water as the water falls to cool it. |

|

Drive Motor |

Spins the fan blades |

|

Spray Nozzles |

Uniformly spreads the water over the fill media or condenser tube bundles |

|

Makeup Water |

Water entering the system. |

|

Drain/Bleed |

Water will be drained from the cooling tower for maintenance purposes but also periodically during normal operation when the level of impurities in the water gets too high. The impurities are from the accumulation of dirt and salts which build up as water evaporates and leaves these behind. This is often referred to as “blowdown” or “bleed” |

|

Basin |

Bottom of the cooling tower, contains all the water in the system when not actively running |

|

Condenser Water Outlet |

Where the cooled water exits |

|

Fill |

What guides the water to the basin as it rains, allows for maximum evaporation increasing cooling tower efficiency. |

|

Filter |

This is where the fan pulls it’s air in from. The filter limits the amount of dirt and leaves entering the cooling tower. Air enters cooler and drier here than when it leaves at the top. |

|

Condenser Water Inlet |

Where the heated water enters ( heated by building use) |

|

Drift Eliminator |

Capture the moisture and water droplets to prevent the loss of process water. Also protects from Legionella spreading by keeping water droplets contained. |

|

Circulating Pump |

Pulls water from the basin back to the top of the fill media to be cooled again. In an evaporative cooler, this is done to raise the cooled water back over the condenser coils. In a traditional cooling tower the circulating pumps taking the water into the building do this. |

If not properly cleaned and serviced, these contaminants can cause blockages and corrosion, which impairs the operating efficiency and can lead to significant damage and possibly failure of the system. When a system is neglected or not cleaned properly, motors burn out. Oftentimes, the damage is so severe that towers need to be rebuilt.

Examples of neglect in a cooling tower can be:

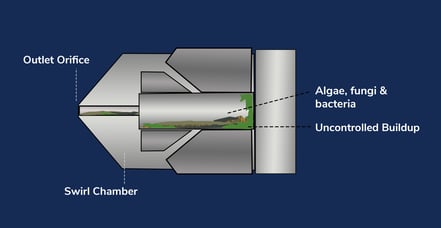

Clogged Spray Nozzles: These spray nozzles spread the water out providing maximum efficiency. If they are not properly cleaned and treated the biological/scale buildup on the nozzles can cause them to not spread as efficiently or at all.

Clogged Spray Nozzles: These spray nozzles spread the water out providing maximum efficiency. If they are not properly cleaned and treated the biological/scale buildup on the nozzles can cause them to not spread as efficiently or at all.

Basin Rust: Without proper treatment the basin can rust causing leaks. More commonly the drift eliminators will show some rust prematurely generally leading to costly replacements.

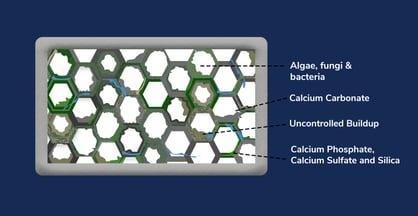

Biological Fouling: Without sufficient biocide in the system biological fouling will occur. This fouling will lead to an abundant growth of algae, fungi, and bacteria on the fill media, reducing efficiency, and in your chiller which will also reduce efficiency.

Biological Fouling: Without sufficient biocide in the system biological fouling will occur. This fouling will lead to an abundant growth of algae, fungi, and bacteria on the fill media, reducing efficiency, and in your chiller which will also reduce efficiency.

Cooling water treatments are generally concerned with regulating the following: alkalinity, chloride, hardness, organic matter, silica, sulfates, dissolved solids, and suspended solids. Untreated cooling towers may develop scaling, which is a breeding ground for legionella.

To maintain the highest standard of quality, cooling towers should be cleaned and disinfected at least twice a year by water treatment experts who can ensure cooling tower compliance with state and federal regulations. Testing is also an instrumental part of proper cooling tower maintenance. Many states are preparing and passing laws to ensure proper cooling tower compliance. For example, in 2015, New York created new requirements for owners of buildings with cooling towers. Local Law 77 (2015) requires registration, inspection, cleaning, disinfecting, and testing of all New York City cooling towers. As states and governing bodies add new laws and regulations, working with water treatment specialists to create long-term maintenance procedures will become an increasingly necessary process.

At IWC, all our treatment plans are tailored to meet your unique needs. Get in touch today to talk about your water treatment needs.

What is a cooling tower? Cooling towers are designed to remove heat from a building. This heat is removed by cooling a stream of water to a lower...

Microbiological Fouling: the undesirable accumulation of micro-organisms, algae and diatoms, plants, and animals on surfaces. Bacteria can form...

Cooling towers play a vital role in various industries, facilitating heat exchange and maintaining equipment efficiency. However, an often overlooked...